Process Safety Considerations for Using Hydrogen as a Fuel Source

By Clare Dunkerley, Process Safety Consultant, Otto Simon Limited

In 2019 the Committee on Climate Change (CCC) issued a report[1] to the UK Government recommending a new emissions target for the UK: net-zero greenhouse gases by 2050. The UK Government and the devolved administrations committed to this new target as recommended by the CCC.

The switch from natural gas to Hydrogen as a fuel source is key part of the UK’s plan to honour the net-zero commitment. Hydrogen has the technical potential to reduce emissions from most forms of industrial combustion, and a report commissioned by the Committee on Climate Change published last year also showed that low-carbon hydrogen has a unique role to play in reducing emissions from direct firing. HyNet is playing a key role in proving this technology, with hydrogen production due to come online by 2025. Nearly £13 million of government support[2] has been provided to develop the design of the hydrogen production and undertake industrial fuel switching trials.

From both a technical and economic point of view, the transition to Hydrogen as a fuel source is a clear part of the roadmap to net-zero. The North West Chemical Industry is in a prime position to hit the ground running. Being geographically close to innovative Hydrogen Projects, such as HyNet[3] and HyDeploy[4], puts members of Chemicals North West close to the growing expertise and skills in the Hydrogen arena.

Safe Handling of Hydrogen

Designers and operators have a duty of care for their employees, visitors and members of the public near the facilities they build and operate. Past Hydrogen explosion events have alerted the public to the potential hazards associated with Hydrogen. Care must be taken to reassure potential users of Hydrogen and neighbours of Industrial Hydrogen users that all necessary measures are being taken to ensure their safety.

It should be no surprise that the key to preventing Hydrogen accidents is no different to preventing other high hazard incidents that already exist in Industrial Chemical Facilities today. The established methods of hazard identification, risk assessment, and applying the hierarchy of controls to ensure the overall risks are at a broadly acceptable level, or as low as reasonably practicable (ALARP), are still applicable. Understanding the inherent hazards associated with Hydrogen is a good starting point to enable comprehensive risk assessment and ensure the design and operation of facilities to prevent, control or mitigate against Hydrogen hazards.

In the UK, the primary regulations that will govern the handling of Hydrogen and the associated infrastructure are DSEAR, COMAH, PER and the Carriage of Dangerous Goods Regulations all of which arise from implementation of EU Directives. There are three threshold values for Hydrogen Inventory that should be taken into account if considering the transition to Hydrogen:

- The controlled quantity of Hydrogen for The Planning (Hazardous Substances) Regulations 2015 is 2 Tonnes.

- Hydrogen is a named dangerous substance under COMAH regulations.

- The threshold quantities are 5 Tonnes (lower tier) and 50 Tonnes (upper tier).

Physical Properties of Hydrogen

The inherent physical properties of Hydrogen provide guidance as to considerations in design.

- Hydrogen is colourless, odourless, and tasteless; making it difficult to detect.

- Hydrogen is non-toxic, does not support life and may act as an asphyxiant. Liquid hydrogen can produce cold boil-off gas, which can produce severe burns upon contact with the skin.

- Hydrogen is extremely flammable in air; the ignition energy is lower than methane and it burns in air with a very hot and almost invisible flame. It has a greater propensity to detonate than mixtures of air with more common flammable fuels.

- Maximum burning velocity of a hydrogen-air mixture is about eight times greater than those for natural gas.

- The low density and low viscosity makes it difficult to prevent Hydrogen leaks. If a hydrogen leak occurs in an open or well-ventilated area its diffusivity and buoyancy will help to reduce the likelihood of a flammable mixture forming in the vicinity of the leak. Hydrogen is likely to pool at high points, such as roof apexes. Hydrogen leak detection should be placed accordingly.

- The dispersion behaviour of a liquid release of hydrogen will be different from a release from gaseous storage. The gaseous hydrogen would be initially very cold, denser than air and start accumulating at low level.

- Liquid Hydrogen carries a potential for rapid phase transition (RPT) explosion.

- Spills of liquid hydrogen can result in air condensing out in and around the pool of liquid.

Hydrogen’s inherent physical properties, much like other flammable compounds such as natural gas, can be safely managed through robust design protocols.

Hazardous Area Classification

Work carried out by HSL for the HyDeploy Trial at Keele University looked at concentrations of up to 20% Hydrogen blended in Natural Gas (NG). The results showed that volumetric release rates could be up to 10% higher for the blend than NG, and dispersion distances (to ½ LFL) could be up to 15-25% further for the blend. HSL proposed pragmatic, conservative modified criteria to be applied at HyDeploy to the Natural Gas Standard IGEM/SR/25 for the blend. Further work will be required to allow these criteria to be used outside the HyDeploy Project.

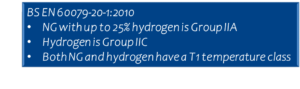

In contrast, standards addressing Hazardous Area Classification for pure Hydrogen or Hydrogen blends above 20% are in wide use already. The Energy Institute (EI) Model Code of Safe Practice EI 15[5] guides that any mixture containing above 30% volume Hydrogen should be treated as Hydrogen. The corresponding EI representative fluid category is G(ii). The HSL tool, Quadvent[6], is also recommended for classifying zones and calculating extents.

Industry Codes and Standards

A number of organisations provide internationally recognised codes with respect to Hydrogen, including; the European Industrial Gases Association (EIGA); the National Fire Protection Association (NFPA) and; the American Compressed Gas Association (CGA). In the UK there is the British Compressed Gases Association, and a number of gas suppliers (e.g. BOC) have their own internal standards. These are particularly useful for identifying requirements for standard separation and segregation distances for hydrogen storage.

Implementing a Hydrogen Economy

Understanding the risks involved with using Hydrogen, and ensuring the necessary steps are taken to mitigate and control the hazards, is therefore vital to enabling the use of Hydrogen as an alternative fuel source.

Further information about implementing a Hydrogen Economy in the North West can be found in the HyNet website, or from the North West Hydrogen Alliance; an organisation created to promote and influence the delivery of a hydrogen economy in the North West region through collaboration between industry, academia and government.

About the Author

Clare Dunkerley is a Process Safety Consultant at Otto Simon Limited. Clare is a TUV Rheinland certified Safety Instrumented Systems Engineer specialising in Functional Safety, including Functional Safety Management, LOPA, SIF architecture design, software specification and functional safety assessment. Clare has a background in DCS and process design engineering, and has worked as lead engineer for relief system studies for multiple clients and DCS and SIS application design engineer for plants in the chemical, petrochemical and waste management sectors.

Clare Dunkerley is a Process Safety Consultant at Otto Simon Limited. Clare is a TUV Rheinland certified Safety Instrumented Systems Engineer specialising in Functional Safety, including Functional Safety Management, LOPA, SIF architecture design, software specification and functional safety assessment. Clare has a background in DCS and process design engineering, and has worked as lead engineer for relief system studies for multiple clients and DCS and SIS application design engineer for plants in the chemical, petrochemical and waste management sectors.

An active member of the North West Hydrogen Alliance, Otto Simon Limited is working at the forefront of technical innovation for the Hydrogen market. We are providing engineering expertise and project management services to develop feasibility, commercialisation, and process safety studies for utilising blended hydrogen and for the re-purposing of equipment to use pure hydrogen as a fuel source for industrial sites in the North West.

Resources

www.hynet.co.uk

www.nwhydrogenalliance.co.uk

www.ottosimon.co.uk

This article was first published in the Autumn 2020 issue of the Chemicals Northwest Element Magazine (ISSN 2396-8567 (Print), ISSN 2396-8575 (Online)).

[1] https://www.theccc.org.uk/publication/net-zero-the-uks-contribution-to-stopping-global-warming/

[2] https://www.gov.uk/government/publications/hydrogen-supply-competition/hydrogen-supply-programme-successful-projects-phase-2

[5] https://publishing.energyinst.org/topics/asset-integrity/ei-model-code-of-safe-practice-part-15-area-classification-for-installations-handling-flammable-fluids

[6] https://www.hsl.gov.uk/publications-and-products/quadvent-2