The North West

Hydrogen in

The North West

The North West of England is poised to be one of the primary regions for the development of a decarbonised, hydrogen-based energy market for the UK. It already features all the necessary components to develop a hydrogen economy – thriving industry, an existing skilled workforce, city regions that collaborate, as well as natural and industrial assets.

A leading energy powerhouse – made up of Manchester, Liverpool, Warrington, Chester, Lancashire and Cumbria – provides a compelling destination for future investment.

Click on the map to view key locations

Industry

Business Parks

Refuelling Stations

Hydrogen Production

Hydrogen Storage

Innovation and Knowledge Transfer Hubs

Net Zero North West

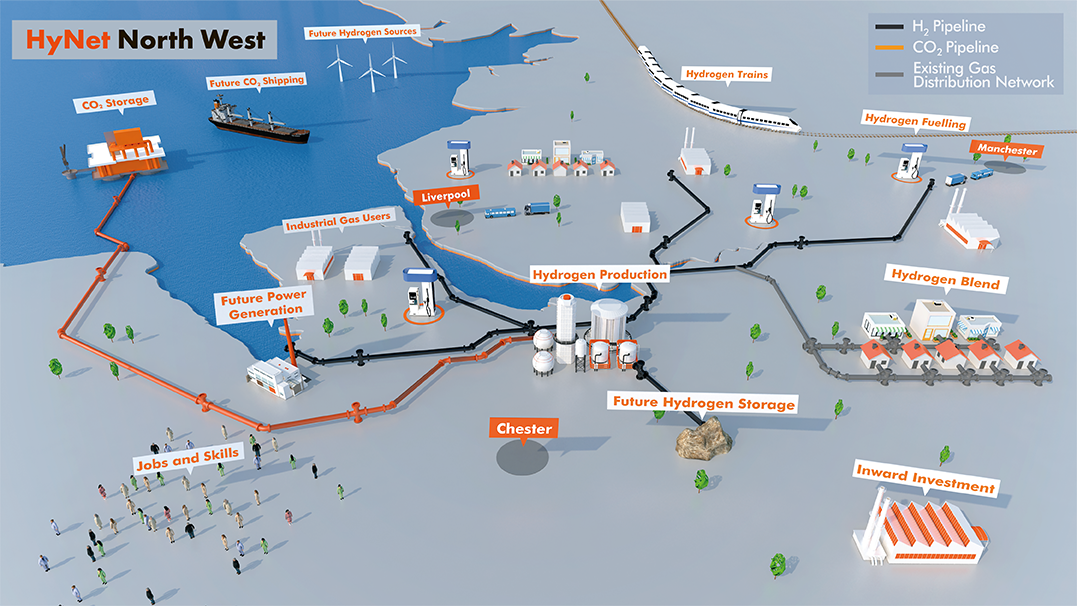

The North West is rising to the challenge of becoming the UK’s first low carbon industrial cluster by 2030. Driven by industry, Net Zero North West is driving investment into the net zero economy and post COVID-19 green recovery. By supporting and safeguarding existing jobs, creating at least 33,000 new jobs and attracting over £4 billion investment, Net Zero North West will be a catalyst for economic growth.

The NWHA is the hydrogen partner of Net Zero North West. A key part of the North West’s decarbonisation approach is the work taking place to develop a hydrogen network in the region through HyNet.

For more information visit www.netzeronw.co.uk.

Hydrogen Projects

Our region is the birthplace of the industrial revolution, historically delivering UK and global firsts in technology. Today, a whole range of projects and initiatives are ensuring the North West is at the forefront of hydrogen development and delivery.

A Regional Economy

Hydrogen could be a lynchpin for growth, boosting the North West’s economy and becoming a magnet for inward investment. Studies show the development of a major hydrogen cluster could deliver £17 billion in Gross Value Added for the North West, creating nearly 6000 jobs.

By positioning the North West as UK leader, the region will unlock significant investment in the development, design and engineering of hydrogen infrastructure.

More details available here

Research and Academia

Esteemed universities and a wealth of innovative research companies mean the region is delivering world first hydrogen technologies.

With academia working side by side with industry, the North West’s institutions can equip the next generation of skilled workers to support the hydrogen economy. Studies have shown that over £7bn could be invested in low carbon skills in the North West by 2050.

Natural and Industrial Assets

A developed landscape of natural and industrial assets makes the North West ideally suited to deliver a large-scale hydrogen economy on a low cost, low risk basis.

Key infrastructure such as the Manchester Ship Canal and the Port of Liverpool offer gateways to hydrogen transportation. These facilities give nearby petrochemical facilities a strategic advantage in the development of carbon utilisation technologies; producing cleaner fuels, polymers and other materials; reducing the amount of CO2 sent for storage.

Geologically, Cheshire is one of the few places in the UK where underground gas storage in salt caverns has been delivered, paving the way for potential hydrogen storage. Offshore facilities in the East Irish Sea can also store CO2 produced from hydrogen reforming.

Across the region, operational hydrogen production facilities are primed to deliver; and existing pipelines are ready for repurposing.

Carbon Capture, Utilisation and Storage

Carbon Capture, Utilisation and Storage (CCUS) is essential technology to help the UK in its fight against climate change. It prevents carbon dioxide entering the atmosphere by capturing it, compressing it and transporting it for safe, permanent storage at carefully selected sites, such as depleted oil and gas reservoirs. CCUS can capture up to 90% of the CO2 emissions produced from industrial processes which use natural gas, such as fertiliser production. As the technology matures, options for the re-use of the CO2 will be available. CCUS is vital for decarbonising: industrial heat and processes; low carbon transport fuels; intermittent and base load power generation; and hydrogen as a low carbon energy vector.

The Committee on Climate Change has recommended that the first CCUS cluster in the UK is operational by 2026 with large scale storage available by 2035. The North West has a cluster of energy intensive industrial gas users around the Ellesmere Port area. Establishing CCUS in industrial areas such as this one maximises potential cost savings and supports the use of the technology across different sectors (e.g. heat and power).

HyNet North West sets out a low cost, practical and timely option for the UK’s first CCUS deployment. Deliverable by 2026, the CO2 will be stored in the Liverpool Bay oil and gas fields owned by Eni. This project is well underway, with the Oil and Gas Authority awarding Eni its carbon dioxide appraisal and storage license in October 2020. The Liverpool Bay site has an estimated CO2 storage capacity of 130 million tonnes. As gas extraction ceases there is the potential to reuse the oil and gas fields to store CO2 which would also avoid or postpone substantial decommissioning costs, payable by Government and industry. A 2016 study by the Energy Technologies Institute cited Hamilton Field at Liverpool Bay as the lowest cost scale UK CCS option (>100Mte.), on the basis of the overall project life cycle cost. There are other nearby opportunities for extension at Morecambe Bay, and the infrastructure could be used by other industry, power generators and in the production of low carbon transport fuels. Read the study here.

Interested in joining?

Whether you’re an academic wanting to share your research or a business keen to support the use of hydrogen in the region, we want to hear from you. Get in touch to see how you could get involved.